Unlocking the Future of Business with Advanced Electronics and 3D Printing Technologies

In today's rapidly evolving marketplace, businesses that leverage advanced technologies such as electronics and 3D printing are setting themselves apart from competitors. Companies like PolygonMach specialize in integrating these innovative solutions into various industries, creating a landscape of endless possibilities. From manufacturing to construction, these technologies enhance efficiency, reduce costs, and foster sustainable growth.

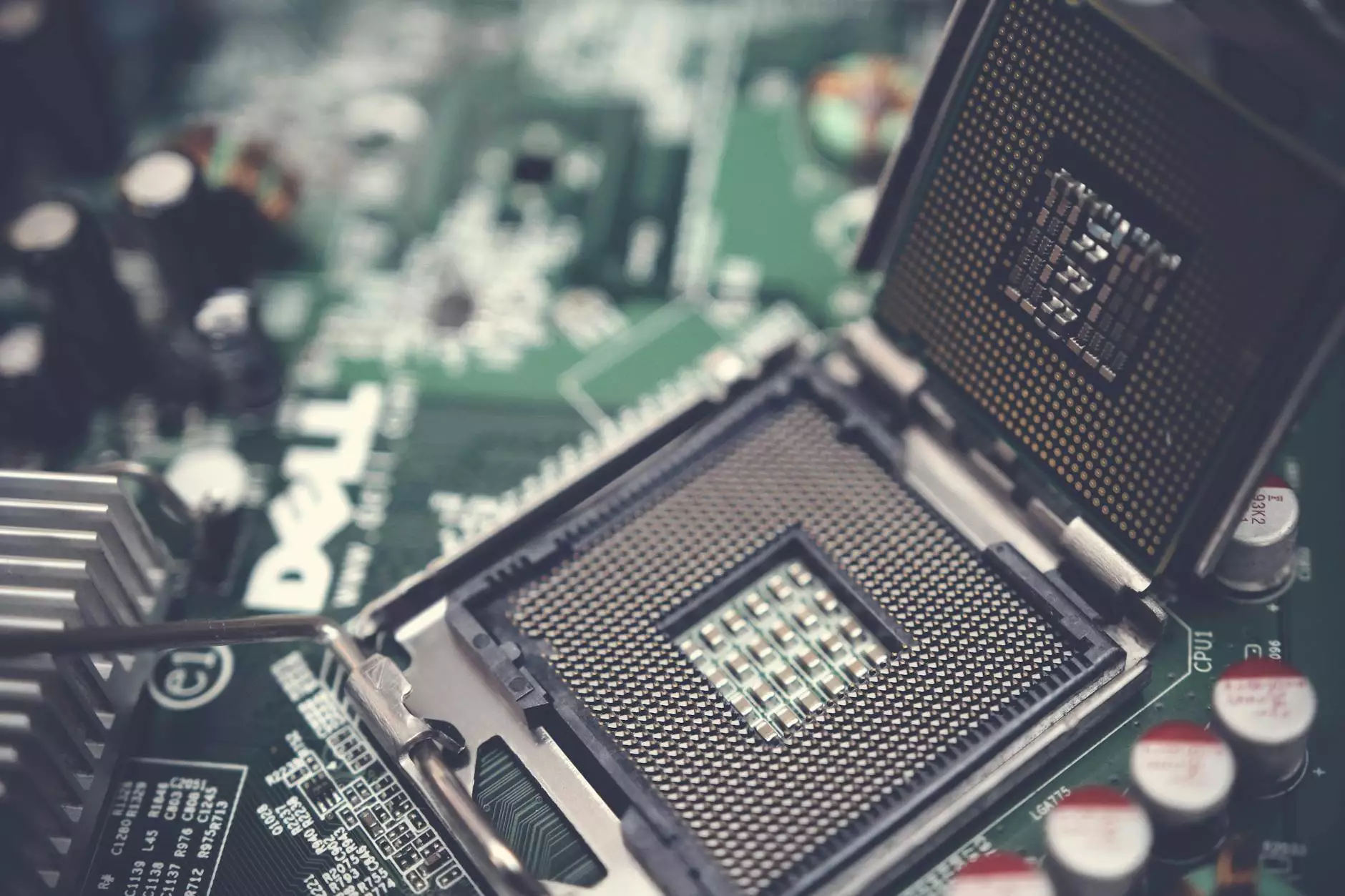

The Transformative Power of Electronics in Modern Business

Electronics form the backbone of modern business operations, enabling automation, improved communication, and data management. Companies in the Electronics sector focus on designing, developing, and implementing electronic devices that meet contemporary demands. Whether it's consumer electronics, industrial automation systems, or smart infrastructure, electronics drive innovation at every level.

Key Benefits of Advanced Electronics Integration

- Enhanced Productivity: Automated systems streamline workflows, reduce manual errors, and maximize output.

- Real-Time Data Insights: IoT-enabled devices allow businesses to monitor operations remotely, making data-driven decisions.

- Energy Efficiency: Modern electronics optimize energy consumption, lowering operational costs and environmental impact.

- Improved Product Quality: Precision electronics ensure high quality and consistency in manufacturing processes.

As businesses adopt smarter electronics, they gain a competitive edge through faster innovation cycles, better customer engagement, and improved sustainability practices. Companies like PolygonMach are pivotal in providing the latest electronic manufacturing solutions tailored for diverse industry needs.

Revolutionizing Manufacturing with 3D Printing Technologies

The advent of 3D printing technology is revolutionizing the manufacturing landscape. It enables rapid prototyping, customized production, and complex geometries that traditional manufacturing can't easily achieve. Industries ranging from aerospace to healthcare are harnessing 3D printing to cut costs, reduce waste, and accelerate time-to-market.

Advantages of Incorporating 3D Printing in Business

- Rapid Prototyping: Design iterations can be produced swiftly, shortening development cycles.

- Cost Efficiency: Reduces material waste and lowers tooling costs for small-batch and bespoke products.

- Customization: Tailor-made products without the need for expensive molds or setups.

- Complexity and Innovation: Facilitates the creation of intricate structures that are impossible with conventional methods.

By integrating 3D printing into their workflows, businesses unlock new potentials for innovation, agility, and differentiation. Companies like PolygonMach offer comprehensive solutions to implement 3D printing technologies across various sectors for optimal results.

Synergy Between Electronics and 3D Printing for Business Growth

The convergence of electronics and 3D printing technologies is opening unprecedented avenues for business development. Combining smart electronics with customized 3D printed components leads to intelligent products, connected devices, and automated systems that are truly cutting-edge. This synergy is especially vital in sectors like IoT devices, robotics, and smart city infrastructure.

Application Examples of Combined Technologies

- Smart Devices: 3D printed enclosures integrated with electronic circuitry create custom IoT solutions.

- Robotics: Rapid prototyping of robotic parts with embedded electronics for faster deployment.

- Automotive and Aerospace: Lightweight, durable components with embedded sensors enhance performance and safety.

- Construction and Infrastructure: Custom-designed structural components and attached electronic systems foster smarter buildings.

Innovative Business Applications of Mobile Cement Silos

Among the critical infrastructure innovations shaping the construction industry is the mobile cement silo. These highly versatile, efficient, and easy-to-transport units have transformed concrete handling, facilitating large-scale construction projects with ease and speed. Businesses adopting mobile cement silos experience numerous benefits that improve project efficiency and reduce costs.

Why Mobile Cement Silos Are Essential for Modern Construction

- Mobility and Flexibility: Easily transported to different sites, reducing logistical bottlenecks.

- Continuous Supply: Ensures a consistent flow of materials, minimizing delays and downtime.

- Cost-Effectiveness: Reduces the need for multiple stationary silos and accelerates project timelines.

- Automation and Safety: Integrates with mobile batching plants for automated mixing, enhancing safety for workers.

- Sustainability: Optimizes raw material use and reduces waste, contributing to environmentally friendly construction practices.

Mobile cement silos are increasingly viewed as a critical asset in large-scale construction projects, especially in areas where rapid deployment, flexibility, and efficiency are paramount. Leading manufacturers like PolygonMach produce high-quality mobile cement silos designed for durability, ease of operation, and seamless integration with other construction machinery.

Factors to Consider When Choosing a Mobile Cement Silo

To maximize the benefits of a mobile cement silo, businesses should consider the following factors:

- Capacity: Match silo capacity to project requirements for optimal efficiency.

- Mobility Features: Look for models with ease of transportation, including wheels or skid-based designs.

- Materials and Durability: Choose high-grade materials that withstand harsh environmental conditions.

- Automation Capabilities: Features like automated loading, discharging, and weighing enhance operational effectiveness.

- Compliance and Safety: Ensure the equipment meets industry safety standards and regulations.

How PolygonMach Leads Business Innovation in Construction and Manufacturing

As a frontrunner in electronics and 3D printing solutions, PolygonMach provides groundbreaking products and services tailored for a wide range of industries. Their expertise extends to manufacturing mobile cement silos that combine technological innovation with reliability and operational ease. PolygonMach’s approach integrates smart electronics for managing real-time data, automation to streamline processes, and precision engineering for durability.

The company's commitment to quality and innovation ensures that clients gain a competitive edge, whether by deploying sophisticated electronics, adopting 3D printing for customized parts, or utilizing mobile cement silos for efficient construction workflows. Partnering with PolygonMach means embracing the future of industrial manufacturing and construction technology.

Conclusion: Embracing Innovation for Sustainable Business Growth

In an era where technological advancements redefine possibilities, embracing solutions like electronics, 3D printing, and mobile cement silos is essential for businesses aiming for sustainable growth and industry leadership. Companies that integrate these cutting-edge tools can expect to enjoy significant advantages in efficiency, cost savings, and product quality. The strategic deployment of such innovations positions enterprises to thrive in a competitive global market.

PolygonMach stands at the forefront of this technological revolution, offering comprehensive solutions that empower businesses to innovate, adapt, and excel. Whether it's developing sophisticated electronic systems, creating bespoke 3D printed components, or providing mobile cement silos designed for maximum efficiency, PolygonMach is your ideal partner in navigating the future of manufacturing and construction.